The last two years have been incredibly challenging for anyone in supply chain. It started with a supply disruption out of China in late 2019 / early 2020. We then went into a demand crisis in April / May of 2020 and then for many industries it very quickly turned right back to a supply crisis. Both with inventories being low and then the entire country trying to restock at the same time which led to too much demand and not enough capacity to move global products. Even US based products were effected because whether made in the US or not, many of the components come over seas.

One hidden part of the capacity issues was the fact that passenger planes stopped flying. In the "belly" of passenger planes flies a lot of cargo and when those planes stopped flying, cargo which normally went by air had to find another way to travel. This added to the supply chain issues.

Much of this has been covered and many articles written so I will not rehash them here. However, what have we learned? What will we do differently? The first thing I think about is crisis management. It turns out, if you are going to be a great supply chain leader, you need to be a crisis manager. That has somewhat always been the case but in the last two years it has gone "mainstream". So, what does it take to be a good crisis manager. Here are my 4 learnings from the last few years:

- Honesty - Be Honest and Straightforward in Communication: This is akin to the idea that you will never solve a problem or deal with a problem unless and until you face up to it and admit it. In your company you need to honest with your executives, your associates, sales and even, yes, your customers.

When these supply issues hit hard two companies stood out: Peloton and Ikea. Both companies went public early on, described what the problem was, what they were doing about it and what people could expect. "Bad news does not get better with age" applies here.

This also applies to associates. Make sure you are honest and straightforward with them as well. - Be Calm and Do Not Panic: Panic is a flight response to an issue that is somewhat embedded in our DNA. However, we as humans can control our responses to anything. This is the time when you have to lead with calmness and strength. Stay focused on the mission(s) at hand. Focus on solving problems.

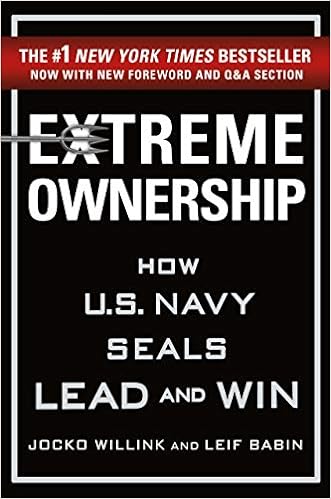

- Be Decisive: You will not have all the facts by the time you need to make a decision. You need to get as much data as possible but when the time comes you are going to have to "make a call". And this is where the job can get lonely - YOU need to make that call. As Matt Damon says in Ford v. Ferrari, "You cannot win a race by committee". You then need to have all your antenna up to read new and conflicting information, synthesize it quickly and adjust if necessary. Procrastination is not a decision.

- Provide a Vision of the Future: Most people understand when a crisis hits and they understand the work is going to get difficult and they are OK with working incredibly hard if they see what the end vision looks like. For example, out of this pandemic and supply chain crisis we will have actions in place to get us through even more difficult times should they come up in the future. The company is going to do great when the consumer hits the great reopening period. Those are two examples of hope and vision.